Friction stud welding a recent variant of friction welding process is ideally suited for naval applications short term emergency repairs submarine resc.

Friction welding of steel to ceramic.

For this reason the literature study included in this thesis also focuses on friction welding of aluminium to steel and aluminium to ceramic.

The process uses friction to create a plastic forming heat at the weld interface.

Of main interest for this work is the welding of steel to a ceramic material such as alumina.

A detailed explanation will be given for the most challenging difficulties like the creation of a brittle intermetallic compound layer in a steel aluminium weld interface and the creation of fatal thermally induced stresses in an aluminium ceramic weld interface.

Of main interest for this work is the welding of steel to a ceramic material such as alumina al.

On friction welding on d issimilar materials.

Almost all research articles that have been found in open literature state that welding steel to a ceramic is nearly impossible without using an interlayer consisting of a compatible metal.

On friction welding on dissimilar materials.

The goal of this paper is to give a clear summary of the literature review performed during the master thesis on friction welding on dissimilar materials.

Of main interest f or this work is the welding of steel to a ceramic material such as a lumina al 2o3 almost all research ar ticles that have be en.

The design of the specimen is modified and ceramic slurry is introduced at the interface in order to achieve increase in joint efficiency and higher joint strength.

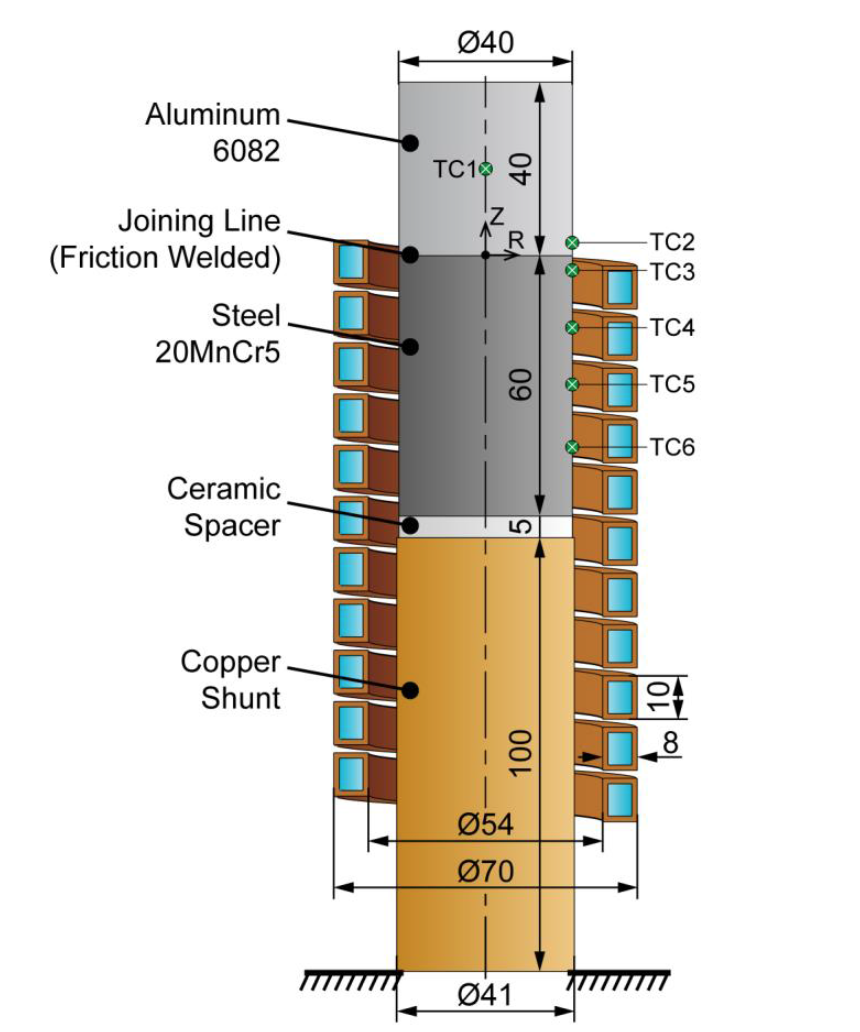

For example ceramic can be joined to steel by means of an aluminium insert which readily welds to both materials.

For example the friction heat created on steel is usually around 900 1300 degree centigrade.

Alternatively friction welding with an insert can be used.

On friction welding on dissimilar materials.