Above is an example of the affect of wear tool life of ceramic with and without coolant.

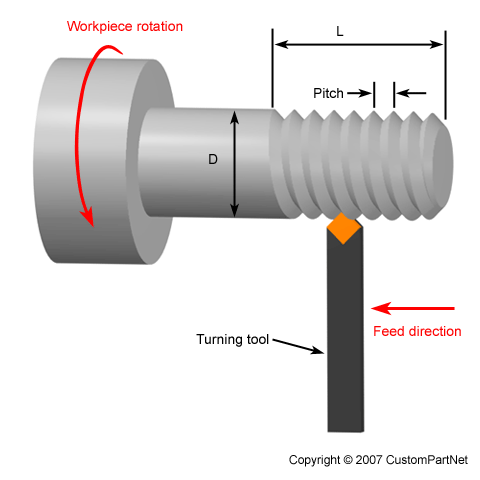

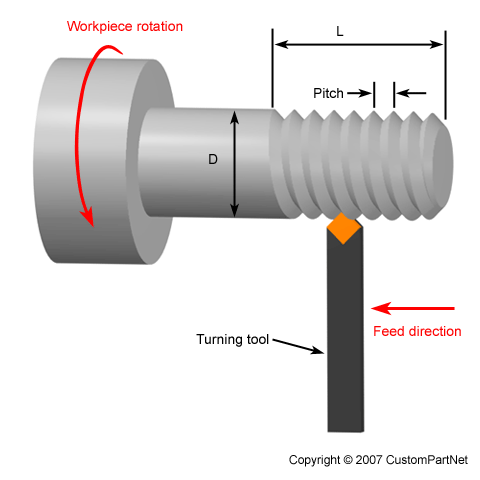

For a turning operation using a ceramic cutting tool.

It is a non rotary cutting tool we can use this cutting tool on shaping planning etc.

The high cutting temperature generated when milling increases the temperature of the chip making it highly sheared.

The example of this kind of cutting tools is the lathe turning tool fixed in the holder and cast non ferrous satellite cobalt etc.

I ve heard so many people say we tried ceramic cutting tools but they didn t work he says.

A left hand tool has its cutting edge formed on its right hand end when viewed from the top with its nose pointing away from the operator.

This is a single point cutting tool that means there will be one cutting edge.

To match the surface speed of a turning operation on a three inch diameter workpiece a three inch diameter milling cutter with four teeth must run four times the turning speed.

Use n 0 5 and y 0 6.

The problem is that better performing options can be easily overlooked or worse dismissed for the wrong reasons.

Threading operations f 0 end cutting edge angle offset shank for facing.

Students should also be able to read and understand blueprints and perform basic shop math.

The most common ceramic materials are based on alumina aluminium oxide silicon nitride and silicon carbide.

Due to intermittent cutting milling ceramics is a much cooler operation than turning.

Carbide is safe and easy to use says steven howard engineering and marketing manager for ntk cutting tools.

For this reason the cutting speed needs to be kept high.

The left hand tool is used for left hand thread cutting operation or turning operation which leaves a shoulder on the right hand end of the workpiece.

Oxide ceramics are used primarily for rough and finish turning for grooving of gray and nodular cast iron and for continuous cutting at high cutting speeds without the use of coolant.

Use n 0 5 and y 06.

Ceramic tools are stable at extreme temperatures as high as 4 000 degrees f unlike carbide and cement tools that contain metallic binders and begin to soften.

Using a carbide tool the temperature in a cutting operation with a speed of 80 ftmin and a feed of 0 03 in rev is measured to be 1200 f.

A left hand tool may also be used for facing operation.

For a turning operation using a ceramic cutting tool if the speed is increased by 40 by what factor must the feed rate be modified to obtain a constant tool life.

Cutting with ceramic tools puts a strain on the machine tool.

With ceramics the object is to generate a threshold of heat per insert.

For a turning operation using a ceramic cutting tool if the speed is increased by 40 by what factor must the feed rate be modified to obtain a constant tool life.

Anatomy of a turning tool most turning is done using a replaceable insert that is gripped in a turning tool body which is.